Preventing the harmful effects of solar radiation on the construction of roofs and walls made of corrugated sheets.

To counteract the creation of large forces in the structure, due to linear expansion of trapezoidal sheets, when designing roofs and walls, it is necessary to provide for appropriate structural protection, of which the most important are:

• odpowiedni dobór długości blach, i.e. the correct spacing of expansion joints for these sheets,

• stosowanie szkieletu dla lekkiej obudowy podatnego na odkształcenia termiczne,

• właściwy dobór blach i łączników ze względu na ich wzajemne oddziaływanie.

Maximum sheet lengths

Maximum sheet lengths

Due to the large lateral bends of the purlins in the middle of the span observed during the tests, as well as torsion of the purlin on the support under the influence of changes in the length of the corrugated sheet, it is necessary to take into account the appropriate selection of sheet length when designing.

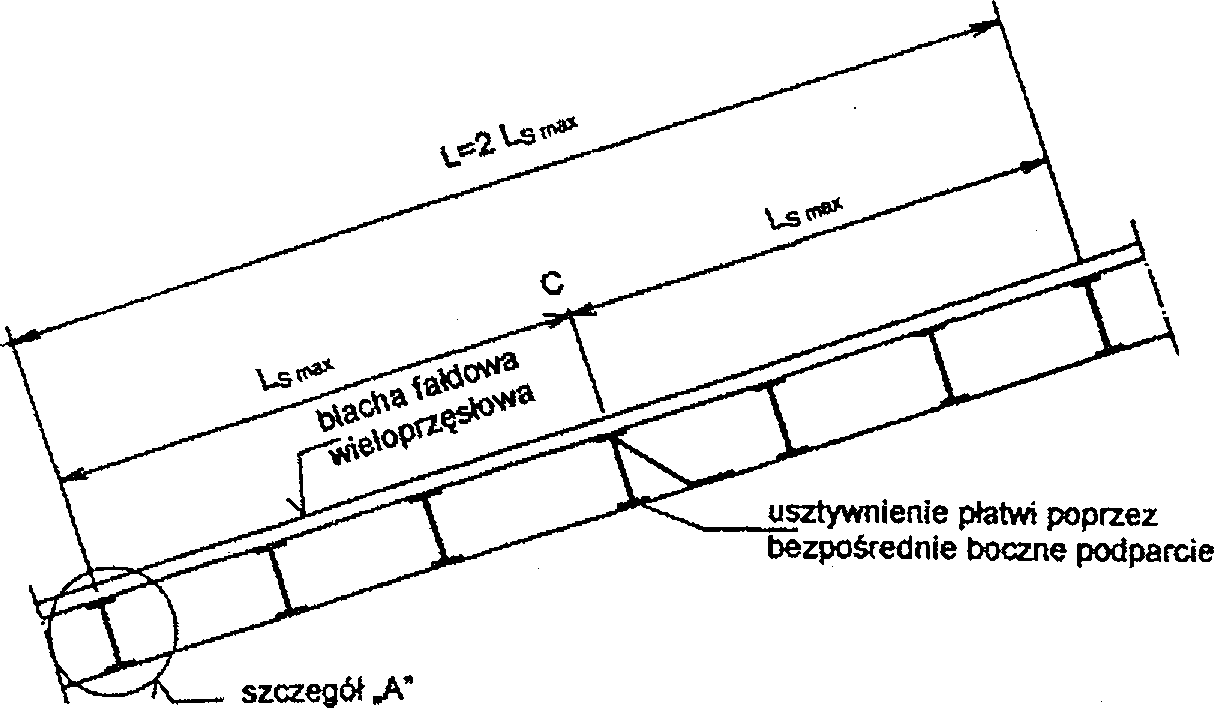

Stiffening of purlins for multi-span sheets together with the principle of accepting expansion joints. At point C there is a non-deformable purlin due to its direct lateral support. The edge of the sheet, after being attached to this stiffened purlin, becomes non-movable.

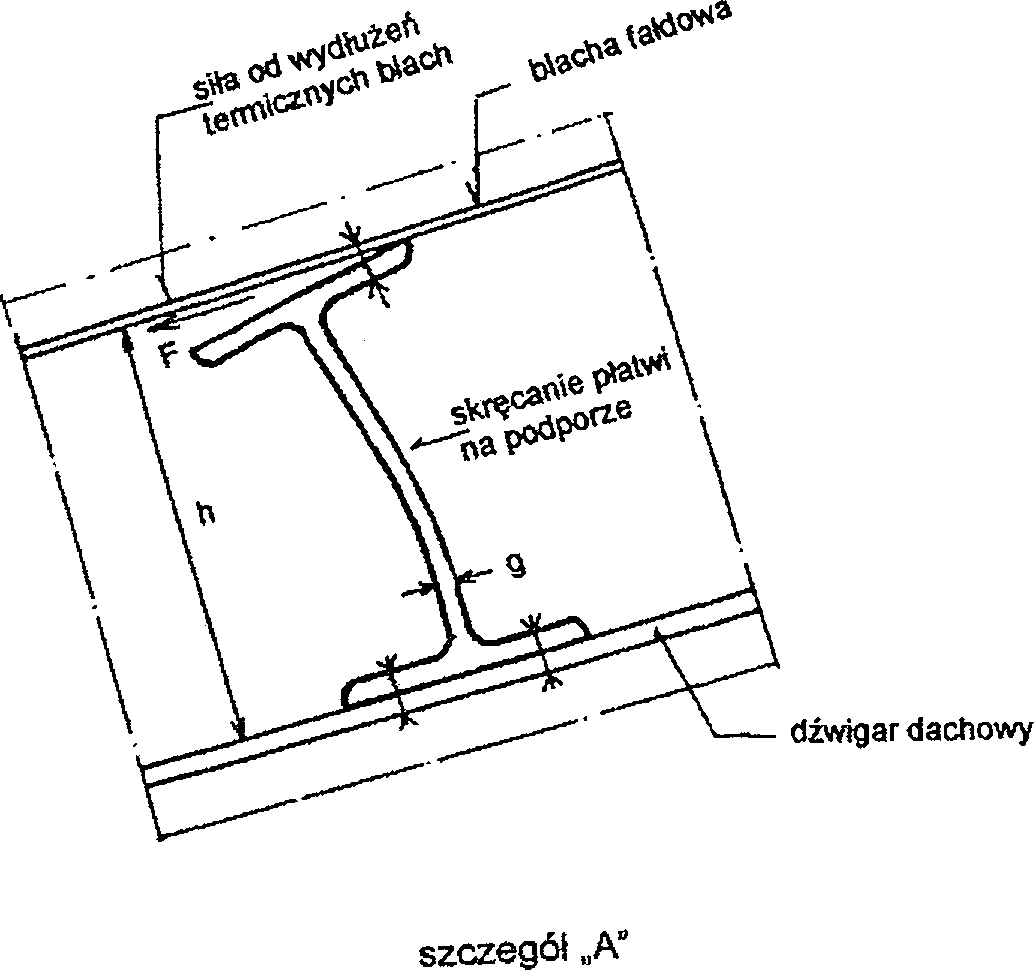

Detail A on  shows the effect of sheet elongation with increasing temperature, which causes one-sided bending and twisting of the purlin. This phenomenon arises then, when the sheet metal and fasteners are sufficiently strong and non-deformable.

shows the effect of sheet elongation with increasing temperature, which causes one-sided bending and twisting of the purlin. This phenomenon arises then, when the sheet metal and fasteners are sufficiently strong and non-deformable.

The table shows the size L of the roofing sheet depending on temperature differences and the size of purlins made of IPE I-section profiles. For multi-span sheets with lengths less than or equal to Lsmax, listed in the table, the effect of additional moments torsion of purlins or girders on supports acting in a plane perpendicular to their longitudinal axes may be neglected, caused by changes in the length of the corrugated sheet.

The greatest permissible sheet lengths Lsmax due to additional stresses in the purlins due to torsion, resulting from the technical elongation of the sheets (steel purlins of Re – 220 MPa)

| Profile – parallelepipeds | Buildings not thermally insulated

ΔT = 40°C Lsmax=[m] |

Thermally insulated buildings

Temp. szkieletu +20°C ΔT=50°C Lsmax=[m] |

| IPE 100 | 3,7 | 3,0 |

| 120 | 5,0 | 4,0 |

| 140 | 6/1 | 5,1 |

| 160 | 7,8 | 6,3 |

| 180 | 9,3 | 7,5 |

| 200 | 10,9 | 8,7 |

| 220 | 12,5 | 10,0 |

| 240 | 14,2 | 11,4 |

| 270 | 16,9 | 13,5 |

| 300 | 19,4 | 15,5 |

For sheets with lengths greater than Ls max,listed in the table, i.e. after exceeding the length of the corrugated metal sheets L = 2L, expansion joints should be provided. If too long continuous corrugated sheets are used, their thermal elongation may have a detrimental effect on the supporting structure of the steel frame and cause the following effects:

• ścięcie łączników lub znaczna owalizacja otworów w blasze fałdowej,

• przekroczenie granicy plastyczności w środnikach płatwi od zginania,

• destruction of fasteners securing the purlin to the girder.

Therefore, the length of the corrugated sheets is limited, already at the design stage, it will protect the steel supporting structures of roofs against excessive deformations and forces caused by the temperature difference between the corrugated sheet and the load-bearing structure.

Expansion joints in the corrugated sheet covering should be used after reaching their maximum length L = 2 Lsmax or denser, np. at the ends of their sheets.